-

×

3d printing resin dental SG100 Surgical Guide Resin 500ml

1 × 1.173.000 ₫

3d printing resin dental SG100 Surgical Guide Resin 500ml

1 × 1.173.000 ₫

Esun Hard-Tough Resin 3d printing plastic (Hard and Tough like ABS) 0.5kg-1kg/Bottle

505.000 ₫–1.000.000 ₫

Đã bán: 0

Esun Hard-Tough Resin 3d printing plastic (Hard and Tough like ABS) 0.5kg-1kg/Bottle

BIG DEAL

Website opening with immediate promotion:

Buy 5 products or more get instant discount 5% each product

Buy 10 products or more get instant discount 10% each product

Buy 15 products or more get instant discount 15% each product

Buy 5 products or more get instant discount 5% each product

Buy 10 products or more get instant discount 10% each product

Buy 15 products or more get instant discount 15% each product

SKU: 1729935330913

Categories: 3D printing plastic, 3D Printing Resin

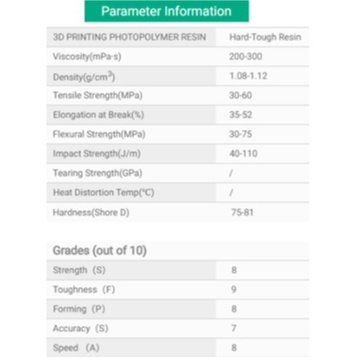

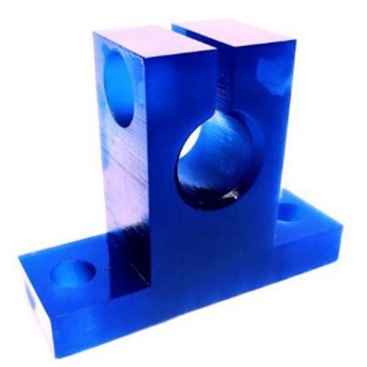

_It is a resin with high physical strength, high hardness and high toughness like ABS filament. Experiments have shown that 3D models produced by eSUN's Hard-Tough Resin, such as aircraft carrier gears, can withstand high impact force and other high-intensity mechanical stress. While using an electric drill to test the toughness of the resin, the model did not break even after several drillings. For the application field, the material needs to have extremely high stress and deformation performance, and that is why eSUN has developed Hard-Tough Resin

_Hard-Tough Resin is a urethane acrylate photocurable resin suitable for LCD printers. To ensure good and stable quality, eSUN is formulated entirely with high-quality imported raw materials with the following advantages:

1. High impact resistance;

2. Higher shock resistance than ordinary plastic;

3. Hard plastic, excellent mechanical properties such as hardness, tensile and flexural strength;

4.High surface hardness and wear resistance

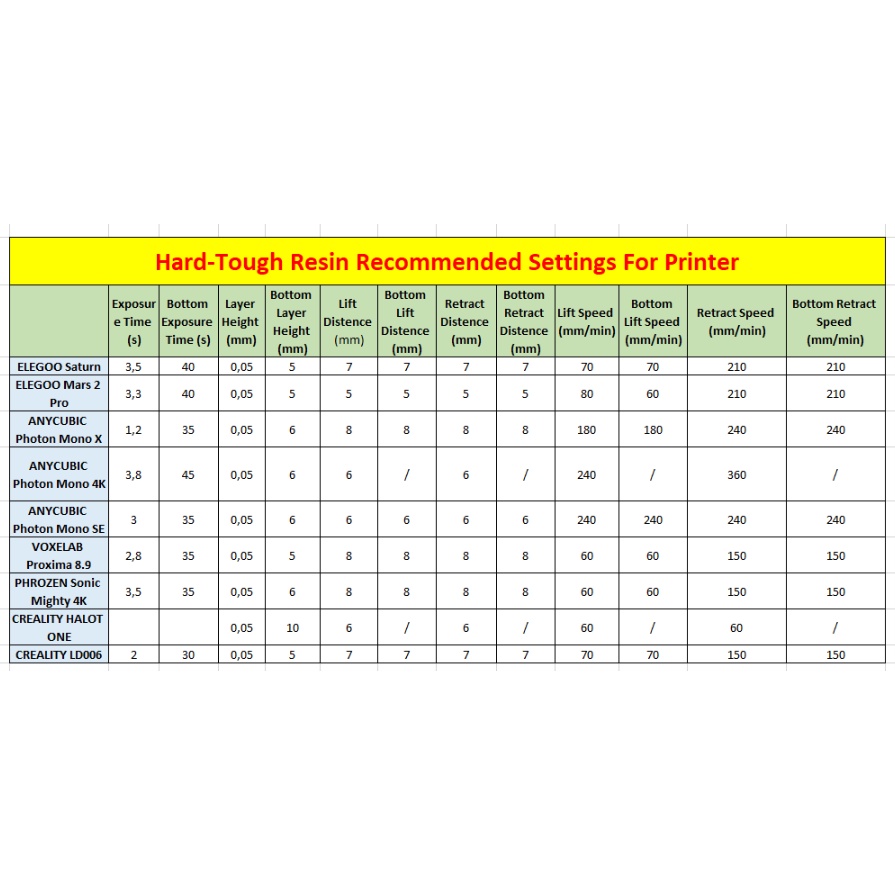

_Print settings:

+Applicable wavelength: 395-405nm

+Operating temperature: 18-35°C

+Exposure time: 20-30s for bottom layer, 8s for normal layer

+Please adjust the settings until you get the best printing performance.

_Instructions for use:

1.Before use:

+Shake liquid resin before use

+Clean the plastic barrel and molding platform to keep the bottom of the plastic barrel transmitting light.

+Please wear gloves and stay in a well-ventilated environment

2.When using:

_Turn the cap on and add it to the plastic tank as required by the device

_Select the correct print parameters and settings for printing

3.After use:

_After printing, please use suitable tools for post-processing, including blades, diagonal cutters, tweezers, containers, gloves; ethanol (≥95%), lactate or isopropyl alcohol cleaning solution; high-pressure mercury lamp or LED lamp (peak emission 360-405 nm); oven

4. Post-processing steps:

A. Remove the printed model from the casting platform with a blade

B. Immerse the model in the cleaning solution, rinse or ultrasonically clean for 1 minute, then remove and drain.

C. Completely immerse the model in distilled water, uniformly irradiate with high pressure mercury lamp, LED lamp, or expose to sunlight

D.Put the model in the oven, set at 50℃ for 20 minutes, then cool naturally to room temperature;

E.Proper processing, such as support removal, polishing, staining, etc.

**Precautions:

1. Seal at room temperature and protect from light to avoid high temperature or sunlight

2.Recommended temperature is 18-35°C, low temperature may affect the printing effect, the resin can be preheated before use (not exceeding 60°C)

3.If the resin pigment settles, it can be used after stirring or shaking.

4.To ensure the ideal performance of the curable material, it is necessary to control the intensity and time of the light source after curing, so we recommend that:

The intensity of mercury lamp or LED light source is 5-10mW/m2, the duration is not more than 1h

+Contact: 0913.939.775 – 094.144.0951

**Selling price does not include VAT (+10% if VAT invoice is issued)

| Weight | 100 kg |

|---|---|

| Color Plastic | Almond Yellow, Beige (Skin), Beige (skin), Black, Black, Blue, Blue, Bright Orange, Bright Yellow, Brown, Clear, Clear (Transparent), Cold White, Dark Gray, Deep Black, Fire Engine Red, Glass Lemon Yellow, Glass Light Blue, Glass Orange, Glass Purple, Glass Watermelon Red, Grass Green, Grass Green, Gray, Green, Green, Gray (Gray), Light Blue, Light Brown, Light Khaki, Magenta (Magenta), Milky White, Mint Green, Natural, Natural (White), Orange (Orange), Peach Pink, Peak Green, Pine Green, Pink (Pink), Purple (Purple), Red (Red), Silver (Silver), Sky Blue, Sky Blue (Sky Blue), Transparent, Transparent (Clear), White, White (White), Yellow (Yellow) |

| Volume | 0.5kg, 1000ml, 1kg, 500ml |

Be the first to review “Nhựa in 3d Esun Hard-Tough Resin (Cứng Dai như ABS) 0.5kg-1kg/Chai” Cancel reply

Related products

505.000 ₫ – 510.000 ₫

Đã bán: 0

314.700 ₫

Đã bán: 0

433.000 ₫ – 435.000 ₫

Đã bán: 0

237.500 ₫ – 475.000 ₫

Đã bán: 0

314.900 ₫ – 320.000 ₫

Đã bán: 0

1.173.000 ₫

Đã bán: 0

789.000 ₫

Đã bán: 0

290.000 ₫

Đã bán: 0

Reviews

There are no reviews yet.